Modular 3D-printed clay for the “Fixing Our Broken Planet” Gallery

The new gallery shows how sustainable, respectful design can successfully coexist within a heritage setting.

Strategies for efficient manufacturing, installation and disassembly at the Natural History Museum

In April 2025, the Natural History Museum (NHM) unveiled a new gallery, made out modular 3D-printed clay elements, that has attracted over 500,000 visitors in less than three months. The exhibition showcases 200 objects from the natural world, research findings from more than 30 Museum scientists and an opportunity for visitors to have their say on the planetary emergency. As a leading global research institution and one of the most visited attractions in the UK–the second in 2024, according to the Association of Leading Visitor Attractions (ALVA), with 6.3 million visitors–the NHM continues to engage the public with the natural world.

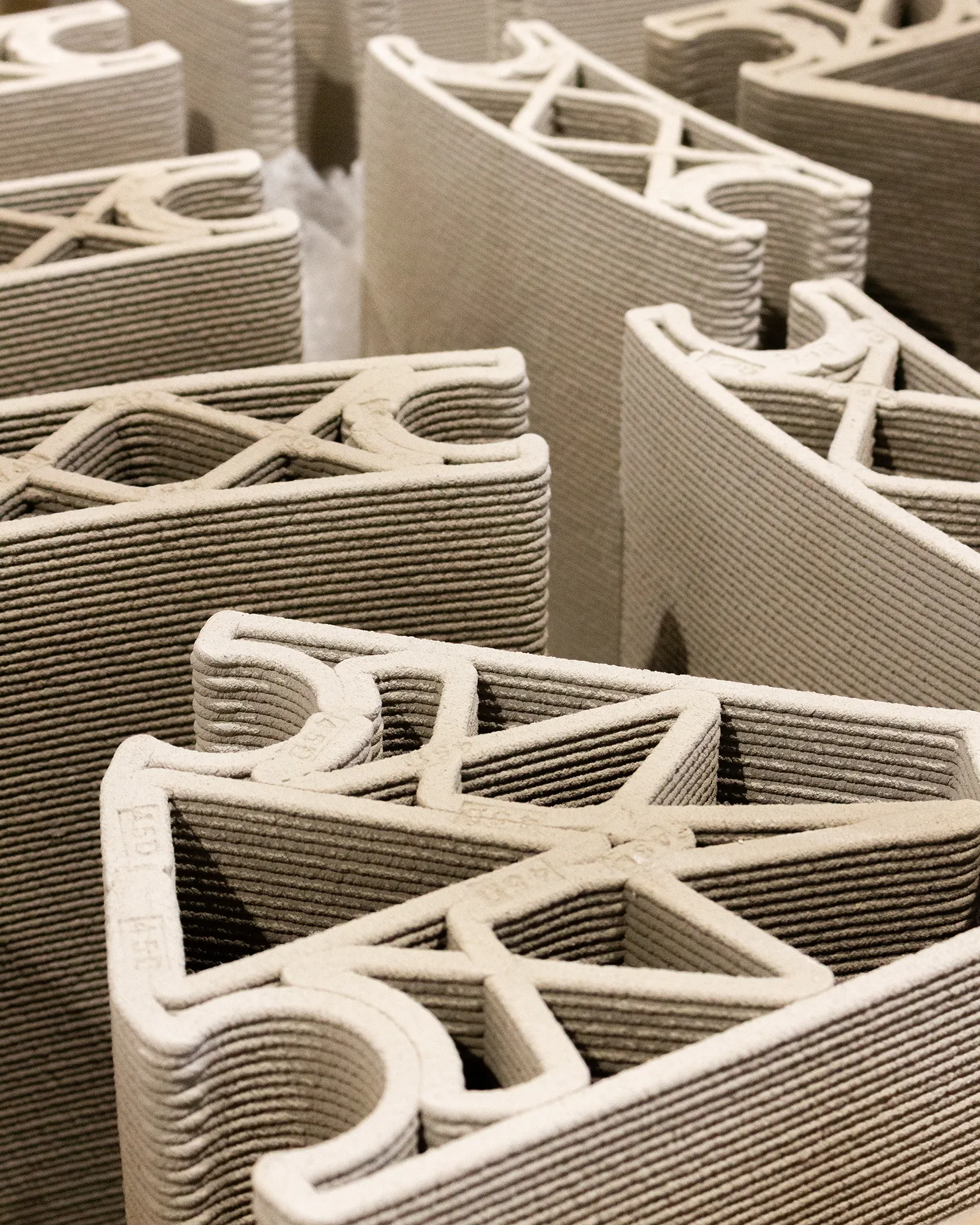

With the opening of the Fixing Our Broken Planet exhibition, the NHM aimed to reaffirm its commitment to sustainability while preserving its Victorian architectural features. After exhaustive studies, the in-house team of architects opted for a design made of 3D printed ceramics. To enhance the efficiency of manufacturing, installation and future disassembly, the design required a modular systematisation.

DIVIDE AND CONQUER

LAMÁQUINA provided a strategic solution by breaking down the gallery layout into ten modular units. This approach enabled the standarisation of each module into individual components, which helped to streamline the whole process. A total of 1,686 pieces were manufactured in less than three months. Thanks to robotic precision, each one was shaped as needed, integrating all technical requirements, including perforations for cables and signage.

Two different clay production techniques were employed: 3D printing for the bases and 2D tiling for top horizontal capping elements. The bases were shaped with specific contours, enabling dry assembly through the use of biopolymer joints. The tiles were designed to bind the structure giving stability to all the modules. This approach not only enables structural integrity but also enables future disassembly, a key principle in sustainable design.

CLAY MEETS CODE

One of the major challenges of using clay for 3D printing is the material’s sensitivity to ambient conditions during production. Each module was monitored at every step to determine shrinkage rates in every direction. This data was coded into the design files to maintain manufacturing within a tolerance of less than 5 mm.

Since the installation was happening within a heritage building, it could make no contact with the walls or impose point loads exceeding 400 kg. The subdivision into smaller elements allowed these constraints to be met during the handling of the pieces during installations.

What sets this project apart is the way it reimagines exhibition design as a sustainable intervention within a heritage site. LAMÁQUINA’s work, merging robotic manufacturing, material intelligence and modular thinking, elevated the NHM’s ambitions from concept to reality. As Alex Burch, Director of Public Programmes at the NHM, explains, it “is designed to spark hope and action.” In a world in need of hopeful narratives, this exhibition stands as a design that can do more than inform, it can empower.

Learn more about this project here.